Sanwa Group's digitalization for traceability and zero defects

Sanwa Group, a pioneer in plastic engineering since its establishment in 1977, has embarked on a digital transformation journey to meet the evolving demands of Industry 4.0. With operations across Asia, including China, India, and Indonesia, the company has consistently pushed the boundaries of excellence to meet the dynamic demands of various industries.

The company has become a leader in providing precision plastic injection moulding, insert moulding, and component sub-assembly solutions. However, the path to sustained growth and operational efficiency was not without its challenges. They recognized the critical need for modernize its operations. Faced with challenges in integrating data sources and optimizing efficiency across its manufacturing processes, Sanwa partnered with Monitor ERP. This partnership marked a pivotal moment in Sanwa's quest for digital transformation and operational excellence.

It wasn't easy for everybody to open their data sources, but the integration of Monitor ERP proved pivotal.

Enhancing order processing and stock level accuracy

Anthony Yeow, the Operation Manager, highlights the significance of Monitor ERP in overcoming initial challenges. As a tier-1 supplier in the automotive and medical sectors, Sanwa Group's strategic imperative behind their digitalization efforts is to align with the demanding standards of these industries. Lim Soon Huat, General Manager, emphasizes that the digitalization process is essential for capturing data related to the stringent requirements of traceability, zero defects, and production efficiency for meeting their customers' exacting standards.

Despite initial hurdles, Monitor ERP seamlessly integrated into Sanwa Group's operations, revolutionizing:

- Order processing

- Financial reporting

- Stock level accuracy

- Better monitor production capacity and machine utilization

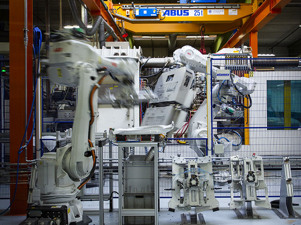

Real-time insights for production capacity and machine utilization

Real-time tracking and identification of operational bottlenecks became possible, marking a significant departure from the manual methods previously employed. With the implementation of Monitor ERP, they now have the capability to track OEE (Overall Equipment Effectiveness) more frequently and identify downtime in real time, whether it's related to machinery or tools.

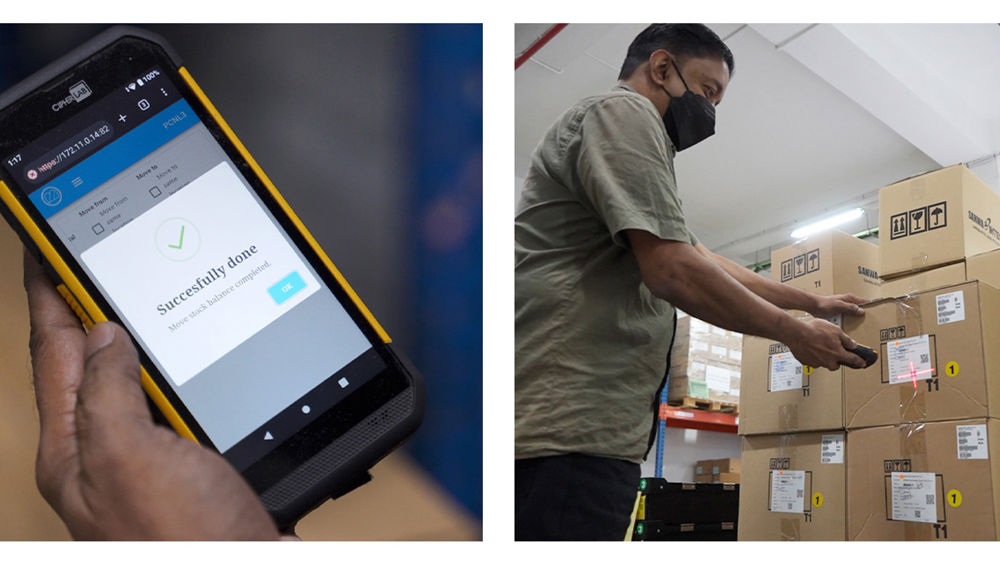

Improved inventory management with barcode scanning integration

On top of that, barcode scanning integration proved to be a critical aspect of the digitalization journey at Sanwa Group. Recognizing its importance, efforts were made to seamlessly integrate the ERP system with barcode scanners and mobile devices, facilitating various tasks including inventory management, receiving, picking, packing, and shipping.

The transformative impact of barcode scanning integration is significantly evident in its efficiency, time-saving benefits, and reduction of manual errors. Now, with a simple input of the part number, the corresponding quantity in stock can be swiftly accessed, streamlining operations and inventory management. This enhanced visibility enables precise tracing of lot numbers, carton by carton, ensuring optimal inventory management and operational efficiency.

"With Monitor ERP, our shipping processes have become more efficient, ensuring on-time deliveries with precision," he adds.

With Monitor ERP, we can ship on time, and 80% of the time, it is perfect.

Isaiah, the Project Manager, highlights the invaluable support provided by Monitor ERP's team in swiftly addressing integration challenges.

The ERP system automated routine tasks, minimizing manual intervention and errors, nurturing a culture of continuous improvement. As Anthony Yeow aptly puts it, "Integrating Monitor ERP motivates us to strive for further excellence, marking a new era of precision manufacturing."

Sanwa Group’s ongoing innovation and excellence are exemplified by their partnership with Monitor ERP, reflecting their commitment to quality, efficiency, and sustainability. Through the strategic utilization of cutting-edge technology and unwavering dedication, Sanwa Group continues to lead the way in precision engineering, shaping the future of manufacturing across Asia and beyond.

(Left image) A group photo featuring Sanwa Group's General Manager, Lim Soon Huat. Right image: Operation Manager, Anthony Yeow stands alongside the Monitor Team.