Becoming the world’s greenest furniture company with Monitor ERP

The Norwegian company Vestre has gone through a lot over its 75 years. Its current focus is to be “the world’s most environmentally friendly furniture manufacturer”. Sustainability is not just a PR-friendly word for them. They work intensely to realize this through concrete actions. This is something they hope to inspire others to do as well – corporations as well as the public.

When visiting Vestre’s spectacular factory site – “The Plus” – in the forest outside the small Norwegian village of Magnor near the Swedish border, it’s easy to be captivated by the awe-inspiring design and placement of the building. Anyone is welcome to walk around the area, and even onto the factory building itself, to see through the many glass walls what’s happening inside, before riding the tube slide down from the roof and stopping for a meal at the 30-meter picnic table, surrounded by tall pine trees.

“One of the key goals for The Plus is to inspire others. Firstly, we want to inspire the public into not viewing industry as some black box with barbed wire around it, but something inviting where you can see how work is progressing and how the employees are treated. It’s also about creating a social meeting place in itself. Being here in the woods and utilizing this area is great for the local population, but we also want to make it a key destination on Trip Advisor for tourists visiting Norway to come and view this,” says Vestre’s CSO (Chief Strategy/Sustainability Officer), Øyvind Bjørnstad. “We want other companies to be inspired by some of the thoughts that lie behind The Plus, which are transparency, openness, and sustainability.”

The factory is built from massive wood and low carbon concrete. It’s a passive house with self-sufficient heating, made possible by reusing the heat generated from heat-intensive processes like powder-coating. Among the grass growing on the roof there are solar panels, which compensate for some of the energy used by the factory.

“We have a goal of producing 120 percent of the energy we consume by 2025. Because we believe companies need to switch to renewables – not just purchasing green energy, but expanding the total grid of green energy. So we invest in green energy projects ourselves,” Bjørnstad explains.

The Plus, Vestre’s factory, is hidden among tall pine trees.

One of the key goals for The Plus was to inspire others.

All the initiatives taken by Vestre are done both because they make business sense, and because a lot of new laws and requirements are being introduced in the near future.

“Hopefully, we can inspire other companies to take similar steps,” he says. “Because a lot of the problem with sustainability is that it’s very fuzzy. You need to get it down to concrete initiatives. Different companies have different starting points and levers that they can pull, to both increase their competitive advantage, and reduce their footprint.”

The fact that Monitor has sustainability high on the agenda is important for us.

Since Vestre restarted its business in 1988 following a bankruptcy filing, its focus has been solely on producing outdoor furniture. Since the beginning, quality and design have been the main drivers. But they have added a third pillar to their competitive edge – sustainability – which they view as “a derivative of quality”, according to Bjørnstad.

“We believe this mixture of quality, design, and sustainability is very potent for growth globally, even when we’re producing here in the Nordics. The fact that Monitor has sustainability high on the agenda is important for us."

Vestre has a clear strategy for growth. They see that social meeting places, as well as the Nordic lifestyle, have an export value. The U.S., the U.K., and Germany are all important markets for expansion. They recently collaborated with Norwegian architects Snöhätta to re-establish the famous New York site Times Square as a public social meeting place, “instead of just cars going back and forth,” as Bjørnstad describes it.

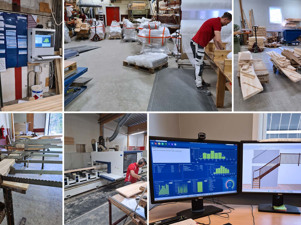

Unlike a software company, upscaling Vestre’s production isn’t done with a simple push of a button. Every single growth percentage point needs to be acquired by actually producing more. And doing it more efficiently. To be able to pull this off, they need an ERP system with the right capability for a state-of-the-art factory like The Plus – a highly automated facility with a workforce of less than 40 people.

“When we are fully operational here, we will have more than 90 percent of the value chain insourced. We have a clear goal of both increasing control for sustainability purposes, but also for efficiency,” says Bjørnstad. “Apart from the assembly process, which is still quite labour-intensive, we can operate the factory with very little manual labour and achieve a lot with advanced industry 4.0 technology.”

One of the key goals for The Plus was to inspire others.

Advanced Industry 4.0 technology is one of Vestre’s strategies for achieving a higher level of sustainability in production.

Vestre recently moved over the last company of the group to Monitor G5, but has not yet utilized it fully or integrated with the whole company group. Until now.

“There’s a big difference between just having an ERP system, and actually learning it and understanding in what way it can rationalize the processes that you have,” Bjørnstad explains.

They are already seeing benefits from having everything on the same system. For example, the simplicity of doing transfers within the company.

“I think having the right ERP system, a system that is fitted to the group, and the production as a whole, is key to being able to unlock the productivity here,” he says. “The automatic exports from the Agent [an option within Monitor G5] are really useful. Monitor is based on production, but utilizing the APIs makes it easy to integrate other systems when needed.”

It's important for Vestre to consider all aspects of – and processes within – manufacturing, when calculating the environmental footprint of each part produced. For example, they purchase low emission steel from SSAB and “Circal” from Hydro, a type of aluminum that has eight times lower carbon emissions than regular aluminum. Having the right suppliers and partners is key to reaching their goal of being the world’s most sustainable furniture manufacturer.

“The fact that Monitor has sustainability high on the agenda is important for us. One of the reasons we built this factory and took control of a bigger part of the value chain is because we wanted to be able to match that with our ambitions on sustainability. And having suppliers and partners that are putting the same emphasis on sustainability is paramount in the years to come,” Bjørnstad adds.

“What lies ahead is no longer just talking about sustainability and having one or two nice initiatives to make PR about. What we see is, it needs to be very concrete, quantifiable, and grounded in science and the most correct possible numbers. For that you need systems like Monitor, that can provide that insight for the company without a massive labor-intensive process.”